Precision Light Duty Lathe Machine

Price 600000 INR/ Unit

Precision Light Duty Lathe Machine Specification

- Product Type

- Horizontal

- Material

- Cast Iron & Steel

- CNC Or Not

- Normal

- Automatic Grade

- Semi Automatic

- Control System

- Human Machine Interface

- Max. Swing Diameter

- 500 Millimeter (mm)

- Voltage

- 440 Volt (v)

- Weight (kg)

- 1350 Approx. Kilograms (kg)

- Feature

- Lower Energy Consumption, ECO Friendly, High Performance, Low Noise, High Efficiency, Simple Control, Stable Performance

- Color

- Pink & White

- Warranty

- Yes

Precision Light Duty Lathe Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Month

- Delivery Time

- 10-12 Days

- Main Export Market(s)

- Australia, North America, Eastern Europe, Western Europe, Middle East, Africa, Central America, South America, Asia

- Main Domestic Market

- All India

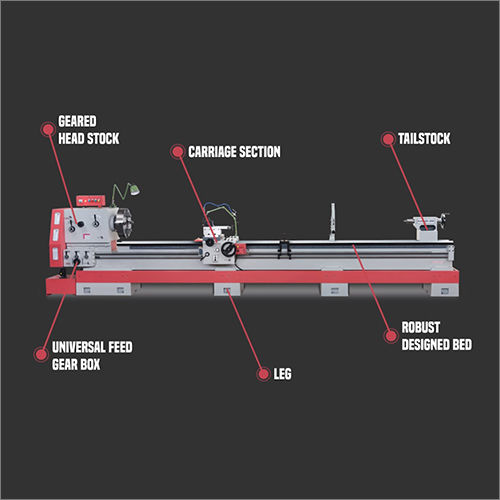

About Precision Light Duty Lathe Machine

We are a prime in offering high quality Precision Light Duty Lathe Machine. The tool is accessible in various specifications as per the need in the operations of cutting, sliding, surfacing and so on. This machine is highly praised for its usefulness, smooth operations, easy installation and excellent performance. It is manufactured with high grade components by our experts. The quality team ensures the machine is free from defects and gives accurate results. Our Precision Light Duty Lathe Machine adheres to the quality parameters set universally which is accountable for its extended working life.

Specifications:

| Height of Centre (mm) | 250 |

| Bed Width (mm) | 280 |

| Distance Between Center(mm) | 1000 / 1500 |

| Spindle Bore & Type(mm) | 55, A2-6 |

| No. of Spindle Speed and Range R.P.M. | 8 (Std) 54-1200, 16(Optl) 71-1600 |

| Universal feed gear box with Inch, MM, DP & Model threads of 106 Type | |

Technical Specifications:

| Description | Pioneer GHL - 250 PL |

| Height of Center (mm) | 250 |

| Swing Over Bed (mm) | 500 |

| Swing Over Cross Slide (mm) | 320 |

| Distance Between Center (mm) | 1000 / 1500 |

| Max. Swing in Gap (mm) | 750 |

| Bed | |

| Bed Type | 2V & 2 FLAT |

| Bed Width (mm) | 280 |

| Length of Gap in front of Face Plate (mm) | 160 |

| Head Stock | |

| Number of Spindle Speeds | 8 (Std.) 16 (Optni.) |

| Spindle Speed Range : R.P.M. | 54-1200 (Std.) 54-1700 (Optni.) |

| Type & Size of Spindle Nose | A/2 - 6 |

| Spindle Bore (mm) | 55 mm |

| Spindle Taper Number | MT- 6 |

| Diameter of Front Bearing | OD 130 X ID 85 |

| Feeds and Threads | |

| Number of Feeds | 76 |

| Range of longitudinal Feeds (mm/Rev) | 0.026 to 0.936 |

| Range of Cross Feeds (mm/Rev) | 0.016 to 0.58 |

| Number of Threads | 106 |

| Range of Metric Threads/No. | 0.2 to 7 mm (33) |

| Range of Inch Threads/No. | 72 to 4 T.P.I. (36) |

| Range of Module Threads/No. | 0.3 to 3 Module (16) |

| Range of D.P. Threads/No. | 44 to 8 D.P. (21) |

| Lead Screw Dia (mm) | 31.75 |

| Lead Screw Pitch (mm) | 6mm |

| Saddle | |

| Cross Slide Dimension (mm) | 178 x 415 |

| Cross Slide Travel (mm) | 225 |

| Tool Shank Section (mm) | 25 x 25 |

| Saddle Traverse (mm) | 870 / 1370 |

| Compound Slide Traverse (mm) | 130 |

| Tail Stock | |

| Spindle Dia (mm) | 50.8 |

| Spindle Taper Number | MT-4 |

| Spindle Travel | 175 |

| Lateral Move of Tail Stock (mm) | 5 |

| Motor | |

| Main Motor (Kw.) | 2.25 |

Salient Features:

| Specifications | PIONEER 250PL GHL-7, 8 |

| Center Height | 250(PL)mm |

| Graded Casting | Yes |

| Head Stock Spindle Speed (RPM) Head Stock Spindle Speed (Optional) | 8 (54-1200) 16(54-1700) |

| Head Stock Spindle is well balanced & Hardened & Ground made from 20mncr5 material mounted on taper roller bearings | A2-6 |

| Universal Feed Gear Box with inch, mm, dp and module thread facility with easy operating speed change with JOY STICK and levers for wide range of threads and feeds | Yes |

| Head Stock Spindle Bore | 55mm |

| No. of feeds | 76 |

| No. of threads | 106 |

| Head Stock Gears & Splines made from 20mncr5 material hardened and ground with profile grinding which is self lubricated | Yes |

| Universal feed Box Gears & Splines made from EN-8 material toughened and mounted on bearings with self lubricated and oil bath.

| Yes |

| Taper wages of SG iron casting in cross slide | Yes |

| Self lubricated fully closed Apron with Drop out type worm with finger tip control | Yes |

| Flame Hardened guide ways bed (Std) Induction Hardened guide ways Bed (Opti.) | Yes |

| Polyurethane paint with International shade | Yes |

| Separate Electrical control panel board with Reverse, Forward, Inching and Emergency stop with SIEMENS Components | Yes |

| Timing Belt pulleys instead of change gears | Yes |

| The Robust designed Tail Stock with Hardened and Ground Spindle | Yes |

| 5 Position Tool Post with in-built indexing | Yes |

| All standard in millimeter | Yes |

| Thread Shaft and Feed Shaft separate for long life | Yes |

| No need to change gears while turn millimeter to inch & inch to millimeter - threads indicated in chart in selective models | Yes |

| Manual Book | Yes |

Enhanced Operational Efficiency

This lathe machine provides superior performance with its high efficiency and stability. The Human Machine Interface allows for smooth and intuitive control, reducing operator fatigue and improving accuracy during machining tasks. Its semi-automatic operation makes it ideal for routine production in busy workshops.

Robust Build for Longevity

Constructed from premium cast iron and steel, this light duty lathe boasts excellent durability and minimal maintenance needs. Its stable structure ensures vibration-free functioning, prolonging the life of both the machine and machining tools, making it a smart investment for various industrial users.

Eco-Friendly and Energy Saving

Engineered for lower energy consumption, this lathe helps reduce electricity costs while supporting environmentally friendly manufacturing practices. The low noise output also makes it suitable for use in settings where maintaining a quieter work environment is important.

FAQ's of Precision Light Duty Lathe Machine:

Q: How does the Human Machine Interface (HMI) benefit operators?

A: The Human Machine Interface (HMI) simplifies control and operation, providing operators with an intuitive dashboard to monitor and adjust lathe functions efficiently. This reduces training time and minimizes the chance of operational errors.Q: What materials can be processed with this light duty lathe machine?

A: This machine is versatile and can work with a variety of materials, including metals such as cast iron and steel, which aligns with its construction and capability specifications.Q: When is preventive maintenance recommended for this lathe?

A: Regular maintenance is suggested based on the manufacturer's guidelines, typically involving routine inspections and lubrication every few weeks, depending on usage intensity and workload.Q: Where can I purchase or inquire about this lathe machine in India?

A: The Precision Light Duty Lathe Machine is available through dealers, distributors, manufacturers, exporters, suppliers, and wholesalers across India. Interested buyers can approach these channels for product demonstrations, pricing, and after-sales service.Q: What is the usage process of this lathe for beginners?

A: Beginners should start by familiarizing themselves with the HMI controls and safety features. After securely mounting the workpiece and selecting the desired settings, the semi-automatic operation helps guide the user through the machining process, ensuring safe and precise results.Q: What are the key benefits of selecting this semi-automatic lathe?

A: Choosing this semi-automatic lathe offers high efficiency, eco-friendly operation, lower energy costs, and stable performance. Its user-friendly interface and reliable construction make it ideal for workshops and production environments.Q: Is there a warranty included with this machine?

A: Yes, the machine comes with a warranty, providing assurance on quality and support in case of manufacturing defects or operational issues.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Precision Lathe Machine Category

Lathe Machines

Price 985000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Weight (kg) : 800 2500 Kg (Approx.) Kilograms (kg)

Material : CAST IRON & STEEL

Product Type : Horizontal

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry

Contact Us

Contact Us Send Inquiry

Send Inquiry Send SMS

Send SMS